The medical sector requires exceptionally high precision, repeatability, and cleanliness.

Medical instruments and implants must meet strict regulatory requirements, including the ISO 13485 quality management system, and guarantee absolute reliability throughout their lifecycle.

Codere SA offers heat treatment equipment specifically designed to support these requirements. With our HTView supervision software, full traceability, advanced data recording, and remote-control functionalities are ensured—matching the stringent expectations of medical device manufacturers.

Aerospace industrie challenges

Manufacturers in the medical sector must meet several critical requirements:

- Full compliance with ISO 13485

- Exceptional surface cleanliness

- Consistent metallurgical properties

- Repeatable, stable thermal processes

- High precision for titanium and stainless-steel components

Codere systems are designed to ensure these conditions while minimizing process variability.

System 300

Our System 300 through-hole furnaces provide high-precision, continuous heat treatment of stainless-steel parts used in medical instruments.

Tempering furnace

The CRG6 series enables tempering and annealing under controlled protective atmospheres, ensuring oxidation-free results and repeatable surface quality.

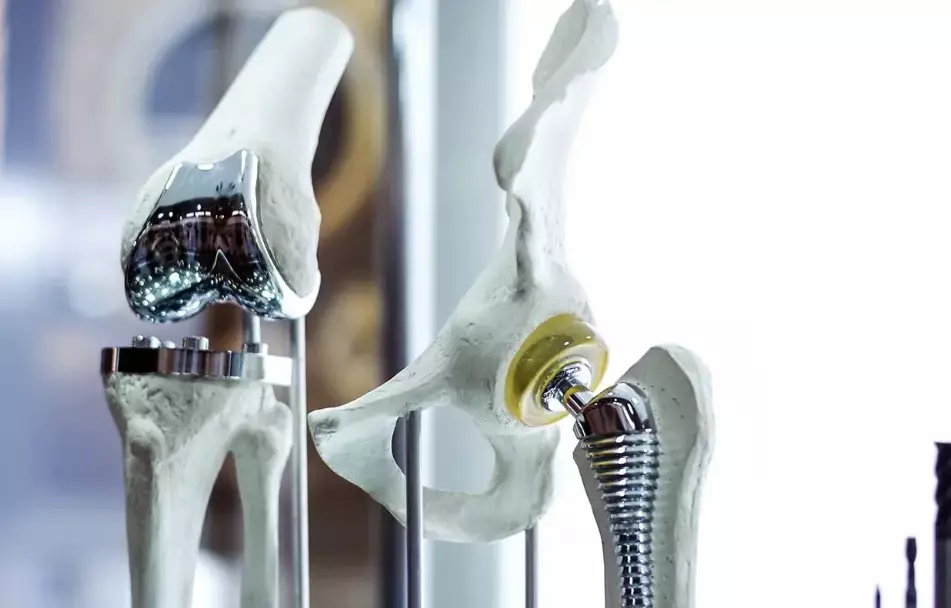

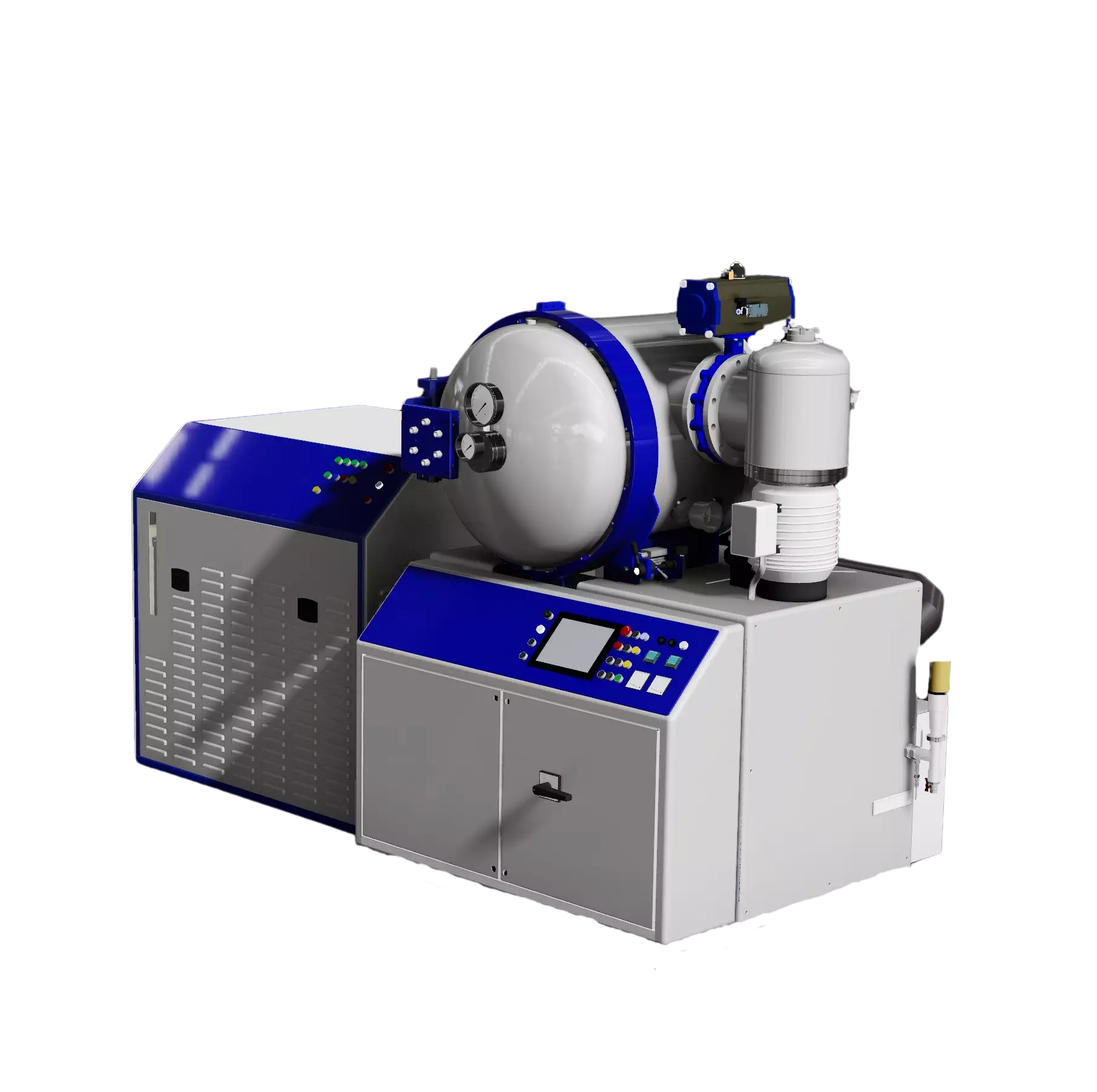

Vacuum Furnace Solutions

Codere also offers vacuum furnace solutions ideal for titanium implants, surgical components, and larger medical parts requiring high cleanliness, controlled quenching, and uniform temperature distribution.

HTView - supervision software

HTView provides full traceability, advanced process control, automated documentation, and real-time monitoring.

It ensures consistent quality, supports certification audits, and guarantees reproducibility across all part types and load configurations.

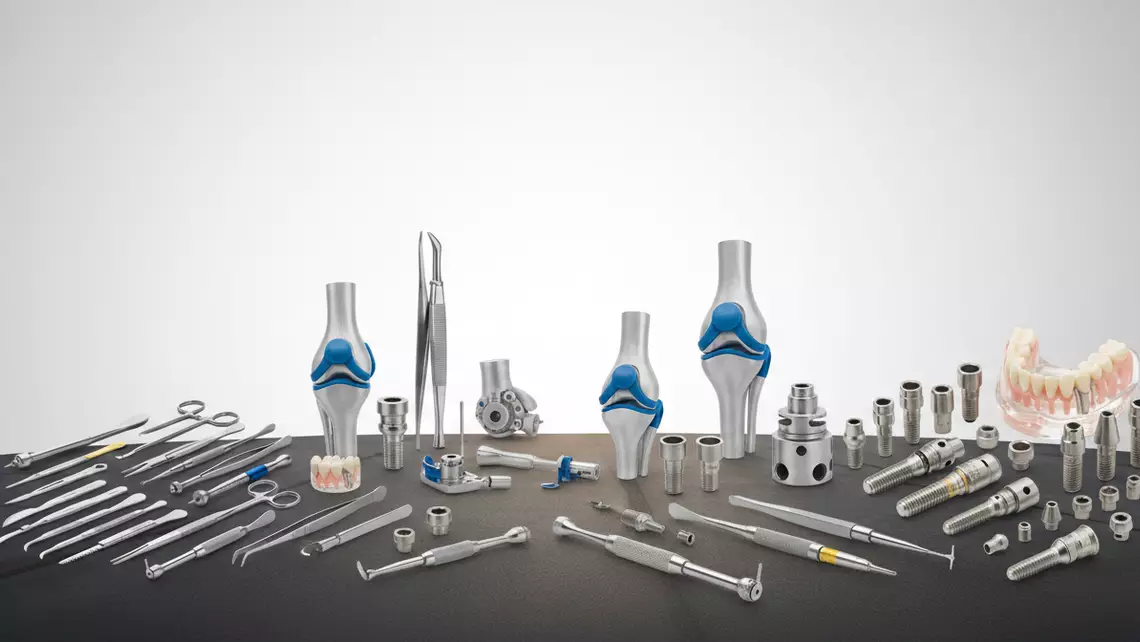

Many possible applications

Orthopedic prosthetic components

Titanium dental implants

High-precision cutting tools for surgery

Key advantages

Full compliance with ISO 13485 requirements

Clean, oxidation-free heat treatment

High repeatability and uniformity

Long service life thanks to Swiss engineering

Complete digital traceability with HTView

Stable, reliable operation for continuous production

Proven Results for Medical Customers

Heat treatment solutions for medical components — superior cleanliness, repeatable metallurgical results, full ISO 13485 traceability, and enhanced long-term reliability.

Codere services

Codere extends the life of your installations with first-class customer service and after-sales support. We help you maximize performance, ensure long-term reliability, and maintain full compliance with aerospace quality standards.