The defense sector is one of the most demanding and technologically advanced industries worldwide.

Components used in military and security systems must demonstrate exceptional reliability, durability, and performance under extreme operating conditions, including high mechanical stress, severe temperature variations, and corrosive environments.

With more than 35 years of Swiss engineering expertise, Codere SA delivers heat treatment systems designed to meet the strictest requirements in the defense industry. Our solutions ensure process stability, tight temperature uniformity, advanced traceability, and full compliance with international quality standards.

Defense industry challenges

Defense manufacturers face strict production and quality constraints due to the critical nature of military systems. Their main challenges include:

- Full compliance with AMS2750, NADCAP, EN 9100

- Complete traceability and documentation of all process steps

- Tight temperature uniformity for high-alloy steels, titanium, Inconel, aluminium, and special steels

- Repeatability of heat treatment cycles for consistent metallurgical results

- Controlled quenching with minimal distortion

- High productivity and low downtime to maintain industrial competitiveness

System 250

Codere’s System 250 modular lines integrate bell furnaces for quenching, washing and annealing, designed for semi- or fully-automatic operation.

HTView - supervision software

HTView ensures full process traceability, advanced data recording, recipe management, and remote diagnostic capabilities.

The system supports certification audits (AMS2750, NADCAP) thanks to complete historical data, real-time monitoring, and automatic documentation.

Key heat treatment processes

Many possible applications

Pistol breech & barrel

Steel/copper casing (ammunitions)

Precision housings, gears, shafts, bearings…

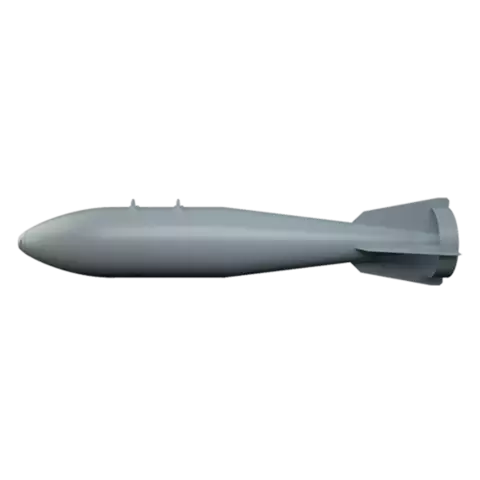

Missile airframe

Small, medium and large caliber cannon

Gun magazine

Key advantages

High precision of metallurgical results

Reduced deformation and consistent quenching performance

Lower your production costs & increase ROI

Autonomous operation with reduced staff

Full compliance with AMS 2750, CQI-9, and NADCAP

Quench transfer in less than 5 seconds when required

Proven results for demanding Defense clients

Modernization of a System 250 line for defense components — improved thermal stability, 100 % process traceability, increased production capacity and significantly reduced operating costs.

Codere services

Codere extends the life of your installations with first-class customer service and after-sales support. We help you maximize performance, ensure long-term reliability, and maintain full compliance with aerospace quality standards.