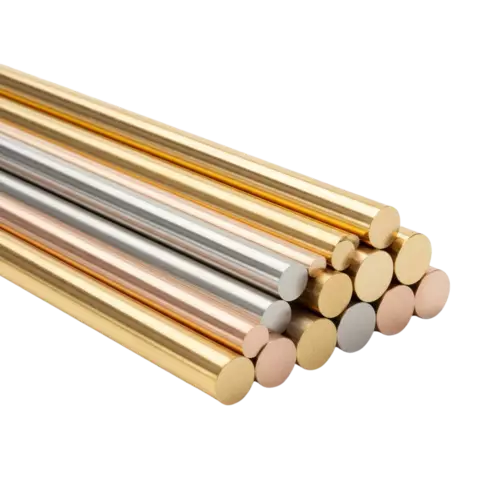

The precious metals sector requires extremely precise heat treatment to ensure perfect ductility, surface integrity, and workability of materials such as gold and platinum alloys.

During manufacturing, intermediate annealing steps are essential to reshape the metal without defects.

Codere’s System 340 annealing furnaces are highly valued by refining houses and precious metal manufacturers. They enable controlled heating below the alloy’s melting point, followed by rapid quenching to restore ductility and facilitate forming or shaping operations.

Precious Metals Industry Challenges

Manufacturers working with gold and platinum face very specific constraints:

- High-temperature annealing without contamination

- Perfect surface condition after heat treatment

- Controlled cooling to avoid oxidation or discoloration

- Repeatable thermal cycles for consistent alloy behaviour

- Ability to process long workpieces such as bars, profiles, and flat products

These requirements demand furnaces capable of delivering both precision and flawless cleanliness.

System 340

Codere’s System 340 furnaces are designed for long precious-metal parts, offering controlled hydrogen atmospheres, clean water quenching, and flawless surface finish with safe, reliable operation.

HTView - supervision software

HTView ensures full process traceability, advanced data recording, recipe management, and remote diagnostic capabilities.

The system supports certification audits (AMS2750, NADCAP, others) thanks to complete historical data, real-time monitoring, and automatic documentation.

Many possible applications

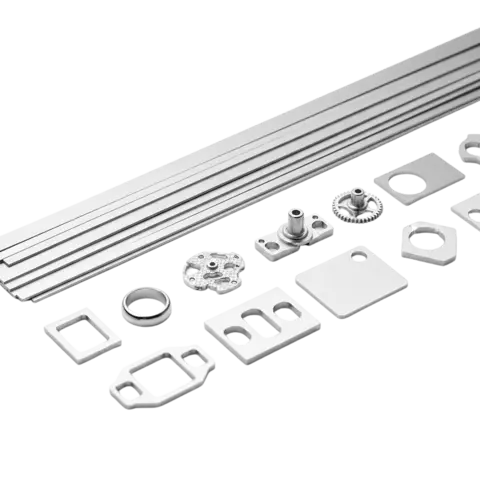

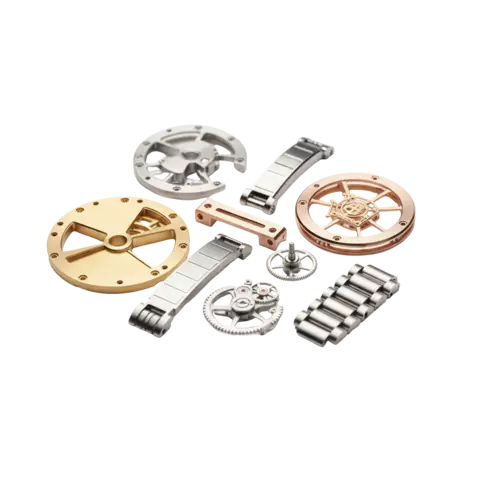

Load of gold-alloy cases (carriures)

Long profiles and bars up to 4 meters

Platinum alloy strips and components

Structural parts for luxury goods and watchmaking

Semi-finished products requiring ductility and perfect surface finish

Key advantages

Perfect surface finish with no oxidation

Excellent process stability and repeatability

Precise temperature control up to 1050°C

Safe hydrogen atmosphere operation

Optimized for long parts and high throughput

Swiss-made reliability and long service life

Proven Results for Precious Metal Manufacturers

Annealing solutions for precious metals — bright, oxidation-free surfaces, repeatable metallurgical properties, reduced scrap rates, and higher production efficiency.

Codere services

Codere extends the life of your installations with first-class customer service and after-sales support. We help you maximize performance, ensure long-term reliability, and maintain full compliance with aerospace quality standards.