The heat treatment of watch components is rooted in traditional techniques and expertise passed down through generations.

Historically, the quality of results depended heavily on the experience of the hardener and the gradual evolution of methods and equipment.

Modern watch manufacturers now rely on high-performance furnaces to ensure flawless metallurgy, repeatability, and compliance with strict safety and quality standards. Codere offers both standard solutions tailored to watchmaking and fully customized systems based on specific technical requirements.

Watchmaking Industry Challenges

Manufacturers face several important constraints:

- Extremely high precision in thermal cycles

- Repeatable results for steels, precious metals, and alloys

- Clean, oxidation-free atmospheres

- Traceability of all treatments

- Compatibility with watchmaking dimensional tolerances and micro-components

Codere systems are designed to support these exacting requirements.

MicroWatch – Hardening Furnace

The new MicroWatch — compact, safe, and easy to use, delivering clean atmospheres, precise hardening results, and repeatable performance for high-quality watch components.

300 – Continuous Furnace

Continuous heat treatment for stainless steel and precious metals — uniform temperature control, high throughput, oxidation-free results, and stable performance for demanding production.

340 – Annealing Furnace

Annealing solutions for precious metals — bright, flawless surfaces, controlled hydrogen or neutral atmospheres, and optimized processing for long gold and platinum parts.

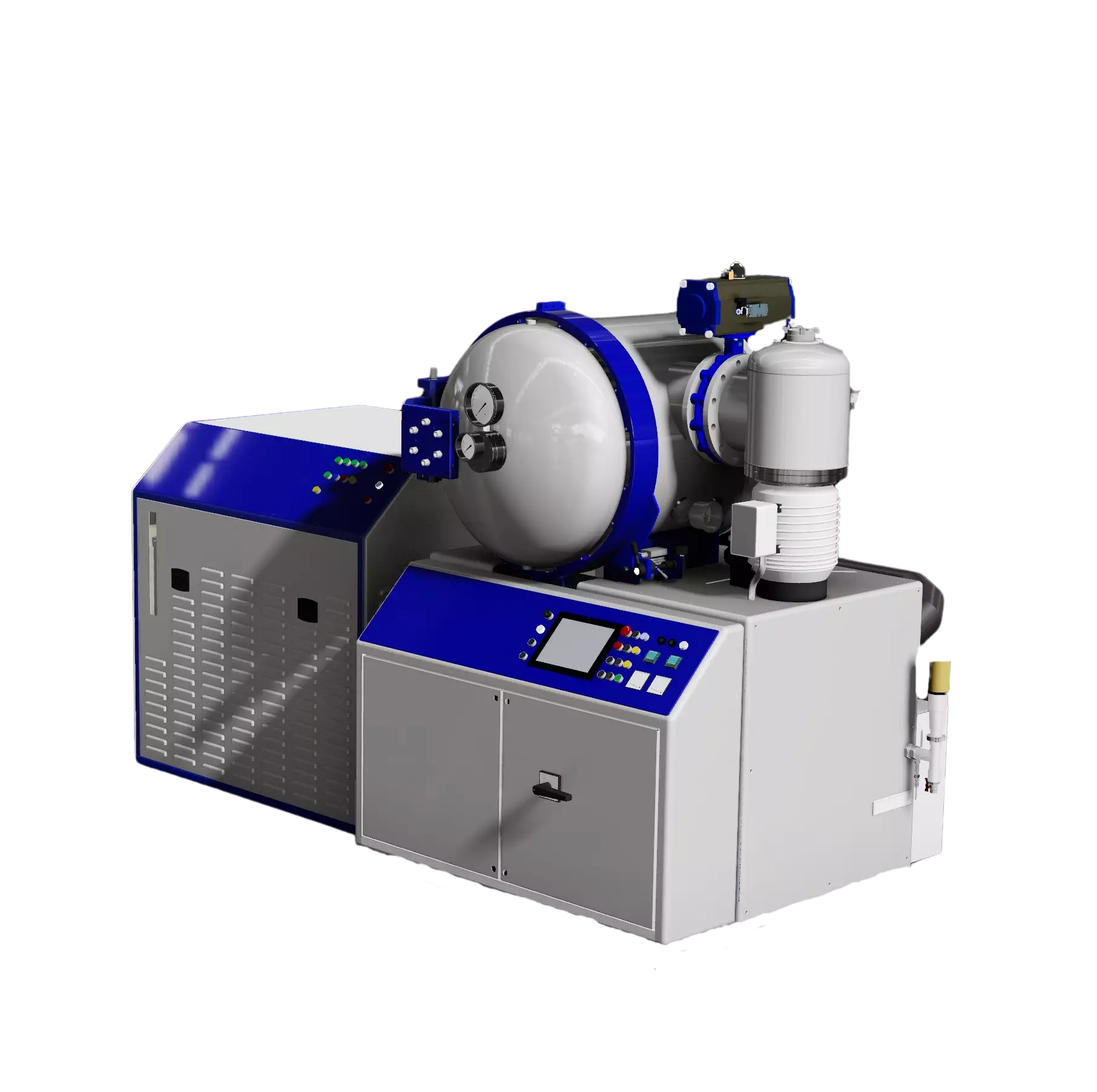

Vacuum furnace

Compact vacuum heat treatment — clean, distortion-controlled cycles for stainless steel, copper alloys, and tool steels, with precise temperature uniformity and fast quenching options.

HTView - supervision software

HTView ensures full process traceability, advanced data recording, recipe management, and remote diagnostic capabilities.

The system supports certification audits (AMS2750, NADCAP) thanks to complete historical data, real-time monitoring, and automatic documentation.

Many possible applications

Gold alloy watch cases (carriures)

Stainless-steel miniature mechanisms

Micro-components requiring tight tolerances

Key advantages

High precision and repeatability

Clean, controlled atmospheres

Traceability through HTView

Swiss-made quality and reliability

Adapted to both small and large production volumes

Full compatibility with watchmaking tolerances

Proven results for demanding Watchmaking clients

Improved heat treatment for watch components — enhanced metallurgical stability, superior surface quality, reduced scrap rates, and consistent long-term performance.

Codere services

Codere extends the life of your installations with first-class customer service and after-sales support. We help you maximize performance, ensure long-term reliability, and maintain full compliance with aerospace quality standards.