At Codere SA, our strength lies in the expertise and dedication of our multidisciplinary teams.

From research and innovation to advanced metallurgy, customer service, digital supervision systems, and precision manufacturing, each team plays a key role in delivering high-quality heat treatment solutions to customers worldwide.

Research & Development (R&D)

Codere’s Research & Development function is a cornerstone of our long-term growth and market leadership. Our R&D team is dedicated to improving existing product lines, integrating advanced heat treatment technologies, and responding proactively to evolving market needs.

A central part of the department’s mission is to collaborate with academic institutions, laboratories, and research partners to foster continuous innovation, develop new processes, and advance our technical expertise.

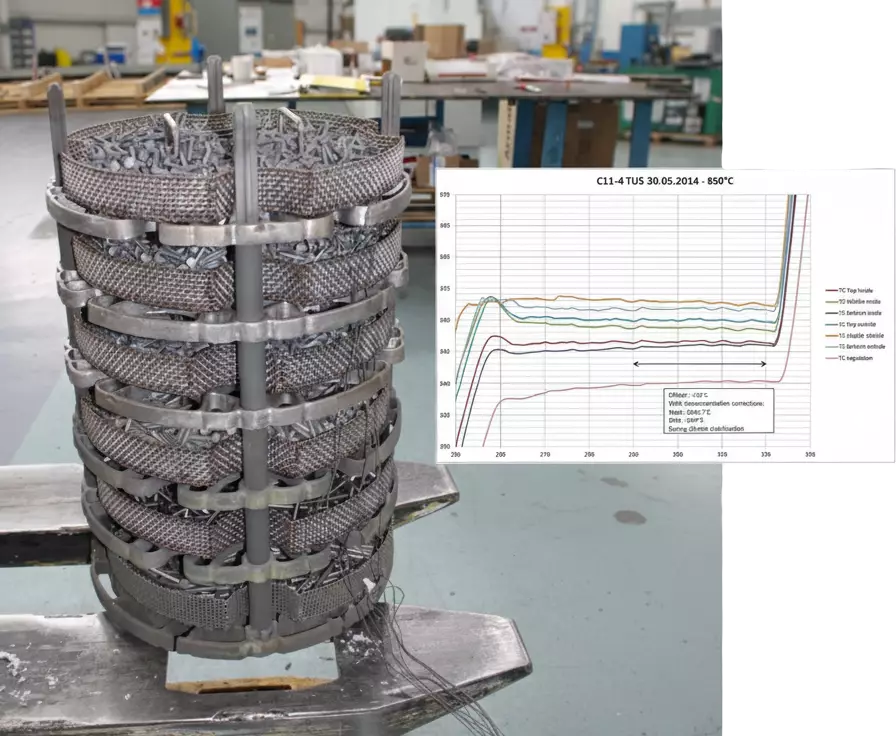

R&D Laboratory

Our R&D laboratory provides specialized services in research, technical calculations, and detailed analyses for a broad range of clients, including industrial partners, universities, and external laboratories.

Thanks to our in-house expertise, we conduct rigorous metallographic testing, support the development of new furnace technologies, and deliver scientifically validated solutions to support both internal projects and customer programs.

Driving Innovation

We engineer innovations that create tangible advantages for our customers. Codere’s strong patent portfolio—covering atmospheric carburizing, carbonitriding, nitriding processes, and specialized heat treatments for ferrous and non-ferrous materials—demonstrates our commitment to delivering high-value, proven technologies to the industry.

Metallurgy Team

Codere’s Metallurgical Team is composed of experienced metallurgists and engineers specializing in the heat treatment of ferrous and non-ferrous metals.

This team provides essential expertise to support internal R&D initiatives and offers consulting services to clients seeking to optimize processes, improve metallurgical results, or solve complex technical issues. Their insight is a key differentiator for Codere and a major contributor to the performance and precision of our equipment.

After-Sales Service

Led by Pascal Daucourt, the After-Sales Service Team ensures the long-term reliability and performance of every Codere installation.

Designed to be dynamic, customer-focused, and highly responsive, the team provides:

- Rapid diagnostics and troubleshooting

- Remote and on-site technical support

- Preventive maintenance

- Optimization and improvement recommendations

Their mission is to minimize downtime, secure production continuity, and act as a proactive partner throughout the entire lifecycle of each installation.

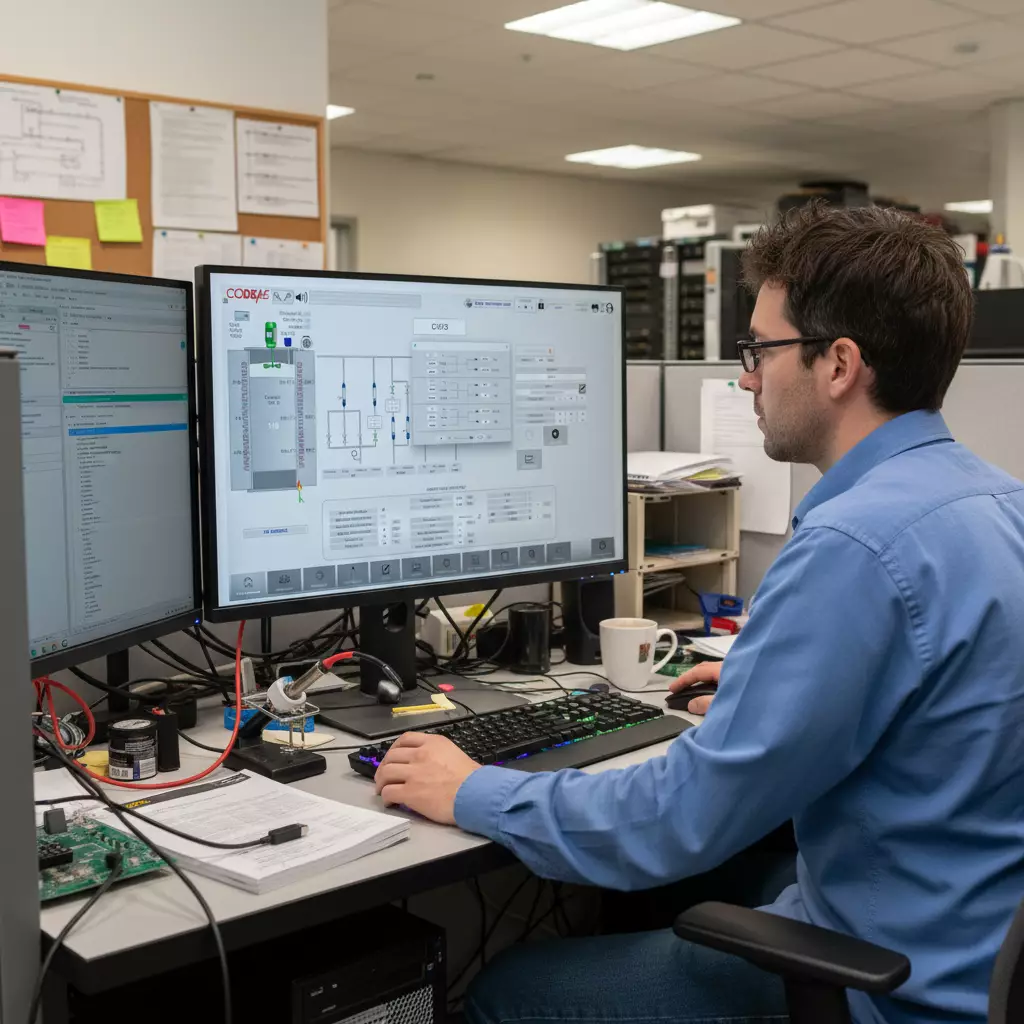

Automation & HTView

HTView is Codere’s proprietary control and supervision software for industrial heat treatment furnaces—including Codere systems and third-party equipment.

While not a traditional operational department, the HTView Team ensures that the system remains flexible, precise, and fully aligned with customer needs.

They develop and maintain the digital backbone of our installations, enabling:

- Real-time process monitoring

- Automated cycle management

- Advanced data logging and analysis

- Integration with quality standards such as AMS and CQI-9

HTView is a core element of Codere’s value proposition, supporting high-quality, repeatable, and compliant thermal processes.

Workshop (Manufacturing & Assembly)

The workshop at Codere SA is the heart of our production operations. Based in Alle, Switzerland, it is where our custom, Swiss-made heat treatment furnaces are engineered, built, assembled, and rigorously tested.

Key functions include:

Manufacturing and Assembly

The workshop transforms designs into fully operational furnace systems, combining precision engineering with Swiss craftsmanship.

Prototyping and Testing

New concepts developed by R&D are prototyped and validated here before being integrated into standard product lines.

Repair and Refurbishment

The workshop handles refurbishment of existing equipment, extending lifecycle and performance.

Quality Control

Every furnace undergoes stringent testing to ensure conformity with demanding standards such as AMS, CQI-9, and Nadcap before shipment.

A Cross-Department Collaboration Hub

The workshop works closely with R&D, Engineering, Sales, and After-Sales teams—ensuring seamless project execution, continuous improvement, and exceptional production quality.